U-ալիքները և C-ալիքները համարվում են կառուցվածքային աջակցման և շրջանակների լուծումների տեսանկյունից ամենատարբերակված և հայտնի պողպատե պրոֆիլներից մեկը: Չնայած դրանք կարող են ունենալ որոշ նմանություններ, կարևոր է իմանալ դրանց տարբեր տարրերը՝ ձեր կիրառման համար ճիշտ տարրի ընտրությունն ապահովելու համար: Մենք Shandong Runhai Stainless Steel Co., Ltd. և մենք առաջարկում ենք պողպատե արդյունաբերությանը առնչվող լուծումների լիակատար տիրույթը, ինչպես նաև պատրաստ ենք օգնել ձեզ հաղթահարել այդ տարբերությունները:

Հիմնական ձևերի ուսումնասիրություն

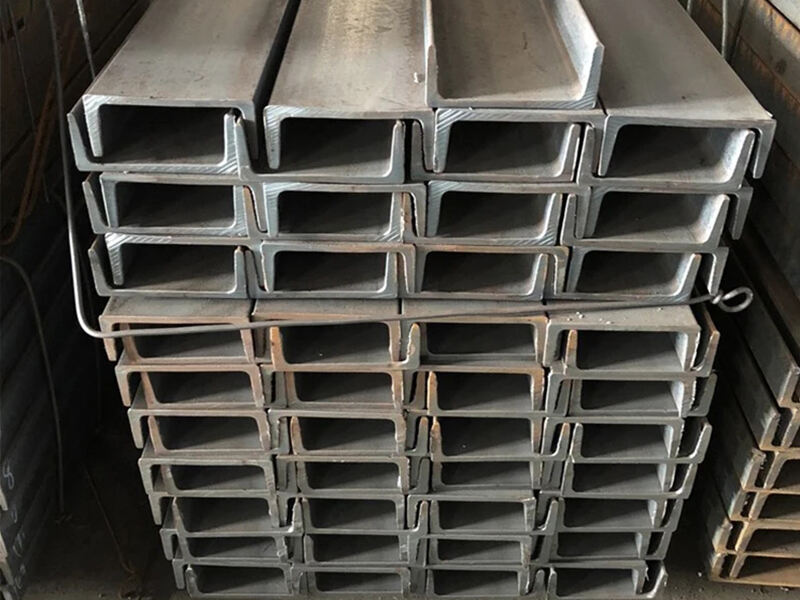

Այս ալիքների ամենաակնհայտ տարբերությունը երկրաչափական ձևն է: U-ալիքը, ինչպես նախատեսված է անվանման մեջ, հատվածքով ունի U տառի ձև՝ ներառնական ցածր մասով, որն ունի երկու զուգահեռ, սիմետրիկ թևեր, որոնք ձգվում են նույն ուղղությամբ: Այս կոնստրուկցիան նախատեսված է թևերի ծայրերին փոքրիկ ծալով, որը ապահովում է մաքուր և համաչափ պրոֆիլ:

C-ձև ալիքը, հատկապես ամերիկյան ստանդարտ ալիքը, թեք է։ Այն չունի զուգահեռ եզրեր, այլ թեքվում է ներս, ինչի պատճառով արտաքին ծայրերում ավելի նեղ է, քան ցանցի հետ միանալու տեղում։ Այս բնորոշ թեքությունը ամենավստահելի տեսողական հատկանիշն է, որը այն տարբերելի դարձնում է U-ալիքից։

Շահագործման և կոնստրուկտիվ վարք

Այս երկրաչափական տարբերությունները ուղղակիորեն նշանակում են կոնստրուկտիվ կայունության անհավասար հատկություններ։ U-ալիքների զուգահեռ եզրերը ավելի լավ արդյունք են տալիս քաշի բաշխման և ոլորման ուժերի դիմադրության տեսանկյունից։ Սա դրանք դարձնում է ավելի կայուն՝ օգտագործման համար այն դեպքերում, երբ կարևոր է ոլորման ամրությունը։ Համաչափ կառուցվածքը ապահովում է կայուն, հարթ ամրացման և միացման մակերես։

Չնայած դրանք փոքր-ինչ թեքվում են, երբ պայմանները հարմար են, C-ձև ալիքները լավ են աշխատում ուղղահայաց բեռնվածության դեպքում: Դրանք այնպես են նախագծված, որ ունենան ամենաօգտակար ամրության-քաշի հարաբերակցություն՝ առանցքի ուղղահայաց առանցքի վրա բեռներ կրելու դեպքում: Սա դրանք հատկապես օգտակար է դարձնում կառուցվածքային համակարգերում, որտեղ հիմնական դիտարկումը կրող քաշն է:

Արդյունաբերության մեջ լայն կիրառություն

Եվ յուրաքանչյուր տեսակի ալիքի ունի իր հատուկ ամրությունները, և հետևաբար կարող է կիրառվել տարբեր արդյունաբերություններում: U-ալիքները հաճախ ընտրվում են մեքենաների պաշտպաններում, սարքավորման շրջանակներում, փոխադրողական համակարգերի աջանկալներում և էլեկտրական տարածքներում: Նրանք համազոր են և հետևաբար լավ համապատասխանում են ճարտարապետական եզրաշերտերի և եզրային նպատակներին, որտեղ համարվում է կարևոր համաձայնեցվածությունը և տեսքը:

C-ալիքները օգտագործվում են շենքերի, կամուրջների, շարժիչների շրջանակների և արդյունաբերական հարթակների հենարանների կառուցման մեջ: Դրանք իդեալական են պահեստաշենքերի, արդյունաբերական շենքերի և ենթակառուցվածքների հիմնական կոնստրուկտիվ համակարգերում՝ բարձր ուղղահայաց բեռնվածության կրողականության շնորհիվ:

Նյութերի ընտրություն և հասանելիություն

Երկու տեսակի ալիքներն էլ գալիս են տարբեր նյութերից՝ համապատասխանեցված տարբեր շրջակա միջավայրի պայմաններին և կիրառման պահանջներին: Ածխածնային պողպատը ընդհանուր շինարարության համար մինչ օրս ամենատնտեսական տարբերակն է: Հակա corrosion պահանջներ ունեցող միջավայրերում, ինչպիսիք են քիմիական գործարանները կամ ափամերձ կառույցները, ավելի լավ են հարմարված ստեղնաշարային պողպատի ալիքները՝ իրենց մեծ տևողականությամբ: Ցինկապատված պողպատն առաջարկում է գերազանց դիմադրություն ժանգոտմանը արտաքին միջավայրում, իսկ ալյումինե ալիքները առաջարկում են թեթևություն՝ այն դեպքերում, երբ քաշը կարևոր գործոն է:

Ճիշտ ընտրություն ձեր նախագծի համար

U-ալիքի կամ C-ալիքի ընտրությունը կկախվի մի շարք գործոններից, որոնք յուրահատուկ կլինեն ձեր նախագծի համար: Օգտագործեք U-ալիք, երբ ցանկանում եք սիմետրիկ թևեր ունենալ՝ հավասար աջակցություն ապահովելու համար, երբ պտտման դիմադրությունը կարևոր է, կամ երբ ցանկանում եք համապատասխան մակերես ստանալ սարքավորումներ և մեքենաներ տեղադրելու համար:

C-ալիքը պետք է օգտագործվի համակարգված կառուցվածքային նախագծերի դեպքում, երբ կարևոր է առավելագույն ուղղահայաց բեռի կրող ունակությունը, կամ երբ կառուցապատման խոշորամասշտաբ նախագծերում արդյունավետ արժեքը հիմնական գործոն է:

Շանդոն Ռունհայի չժանգոտվող պողպատի ընկերությունում մենք հասկանում ենք, որ յուրաքանչյուր նախագիծ իր հատուկ պահանջներն ունի: Մենք ունենք մեծ պաշար՝ բոլոր չափերի և նյութի U և C ալիքներով, և դուք անպայման կգտնեք ձեր կիրառման պահանջներին համապատասխանողը: Մեր տեխնոլոգիական թիմը պատրաստ է խորհուրդ տալ և օգնել ձեզ ընտրել ճիշտ պողպատե արտադրանքները ձեր շինարարական, արտադրական կամ արդյունաբերական նախագծի համար:

Վերցրեք գիտակցված որոշում ձեր կառուցվածքային պահանջների վերաբերյալ: Զանգահարեք մեզ հիմա, որպեսզի իմանաք, թե ինչպես կարող է ձեր նախագիծը հաջողությամբ իրականացվել մեր պողպատե ալիքավոր լուծումների օգնությամբ՝ համապատասխանելով ձեր հատուկ պահանջներին:

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

BN

BN

BS

BS

LO

LO

MN

MN