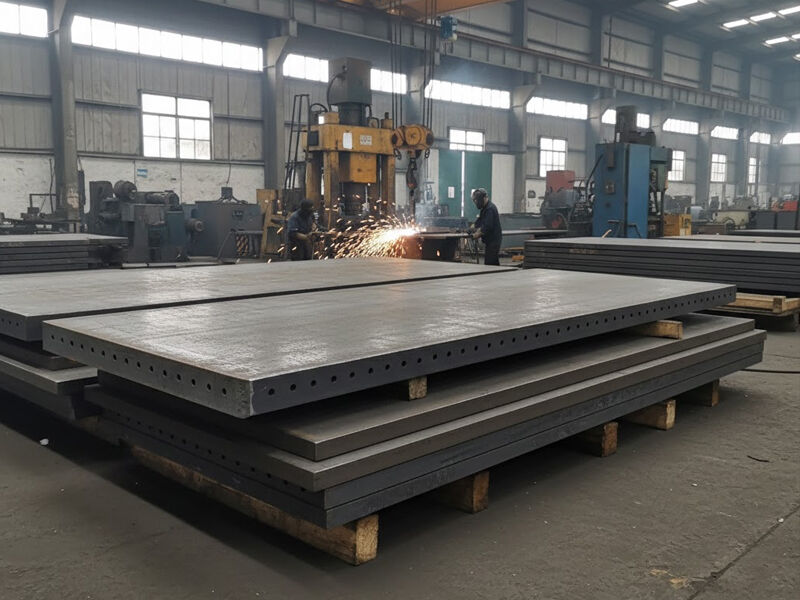

Choosing an appropriate thickness of a wear-resistant Steel Sheet is rather urgent because it will determine the performance, prices, and durability of the project. The correct thickness is applied to ensure that the level of abrasion, impact, and fatigue resistance would be elevated in the case of mining equipment, construction and handling equipment, and industrial flooring. As this guide will demonstrate, there are certain main factors which must be considered in the attempt to reach an informed decision, according to the engineering principles and actual implication.

Understanding Wear Resistant Steel

Wear resistance steel (also known as AR steel or Abrasion Resistant) is a high-carbon alloy steel, which is used because it must resist the extreme wear of a surface by friction or scraping or by high impact. One of the most significant factors that prove it to be resistant to the abrasion of its material, may be its strength that is usually measured on Brinell (HB) scale. The hardness is not the only item needed in conjunction with the thickness needed. The hardness of the sheet is added to the thickness strength to achieve the structure and the strength of the sheet to complete some number of services.

The Factors to Know Thickness Selection

The Definition of the wear mechanism: What is the Type and Severity of Wear?

Pure Abrasion/ Sliding Wear: This has the using extremely high hardness sheets of the highest hardness (e.g. 500 HB) so that one is not hitting the abrasion.

Impact Wear: This one is achieved by striking hard and sharp materials onto the surface or grand material. This implies that it should be made thick enough that it does not creep out, distort and fissure at the ends at the bottom of the hardened surface.

Combined Impact and Abrasion: the most common and the most difficult Thickness in this case is a factor of significance because it must be in a position to absorb the impact energy and at the same time should possess long term abrasion resistant surface.

Load and Impact Energy: It is known that the calculated kinetic energy of the colliding materials (mass, velocity, drop height). Large loads and increment of impact demand the greater grades of the plates to add up so that they will not be perforated and softened in plastic. The negotiations of structural engineers by formula, or industry standards, tend to have an influence on energy and minimum material-thickness and toughness.

Hardware and Application design:

Part Appearance: e.g. liner, bucket wall, section walking groove or other structure? Liners may be detachable and we may have a case where they may be made of thinner materials and structural elements must be heavy to be able to sustain loads.

The Support Structure: This is determined by the thickness as well as the spacing of the supports (girders, ribs) and is what determines the degree of bending strain that the sheet will experience. To design a support panel consisting of a support panel and but lengthening the spans of the support to avoid flexing a support panel, a finer gauge support panel may be prepared.

Service Life: Expected Service Life- state the life which is required before service. The sheet is typically guaranteed as having a high level of warrant that ensures the longevity of the service that reduces the time out and cost of replacing the employees.

Fabrication: Fabrication is never accompanied with signage changes. Installation: There are no signage changes with fabrication.

Welding and Cutting: Thick plates will be subjected to more complex welding (pre-heat, special electrodes), which will contain the hydrogen that will lead to cracking of the parts especially in the Heat-Affected Zone (HAZ). Consider the store capacity or the contractor capacity.

Limitations of the gravitation: The sheets are dense of immense weight. This has the effect of affecting the payload and fuel economy of whatever applies to mobile equipment (e.g. trucks or excavators). Best thickness includes a trade off between working weight and working life.

Formability: The harder and thicker steels are less formable and in the event that one part is required to be bended or shaped, then it may require special treatment.

A Practical Step-by-Step Approach

Investigate Operating Environment: Document the nature of employment materials, size, shape, hardness and movement (sliding, free-fall, rolling). Cost-Benefit Analysis (Total Cost of Ownership): It is important to consider the initial price when buying a Steel Sheet, and do an extensive analysis using the Total Cost of Ownership. The reason is that a heavier or more refined Steel Sheet would be relatively costly but expensive in the short term, although the short-term expense may be recovered by large-scale saving in the long-run. These savings are achieved by less time spent in production wastes, less costs in replacements and less labor hours in maintenance and installations to be done later. When choosing a better Steel Sheet initially, this would be a wise move and would most likely get high returns within the lifetime of the product.

Conclusion: Precision in Selection Ensures Value

The issue of wear resistant steel thickness does not lie in the selection of the most thick type of the wear resistant steel because the most thick wear resistant steel is the best but the issue lies in the choice of the material in regards to the requirements of the work and the technical characteristics. It is also a good option and it is a complex of the economics of materials science and applied engineering. The partnerships with a professional supplier are to be accomplished to the projects, which presuppose the use of good performance and wear resistance steel that is highly reliable. The Runhai Steel is equipped with massive stocks of steel products with wear resistant grades and can deliver its products to its customers in the chemical, pharmaceutical power and construction industry. In making decisions in specification we offer the right access to the required materials with the help of the technical assistance based on the customer and warehousing management system which we designed. It is our business to provide you with the material of giving you the right content to what you want in your business which is valuable and lasts long.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

BN

BN

BS

BS

LO

LO

MN

MN