RUNHAI STEEL

Your Reliable Steel SupplierRunhai steel is not only a professional steel supplier, but also your trustworthy partner in China. We ensure quality and quantity, provide material certificates, and will refund if the products are not qualified, so please be assured the purchase. Regarding long-term cooperation or large orders, you can contact us for additional discounts.

Enjoy Bulk Order DiscountsFOUR REASONS TOCHOOSE US

-

AAA Level

Credit Steel Supplier

Gold Certified Merchant

-

20+

Have our own R&D team

Large inventory Warehouses

-

Support

Three-party Inspection

-

Large Order

Preferential Policies

Get in touch

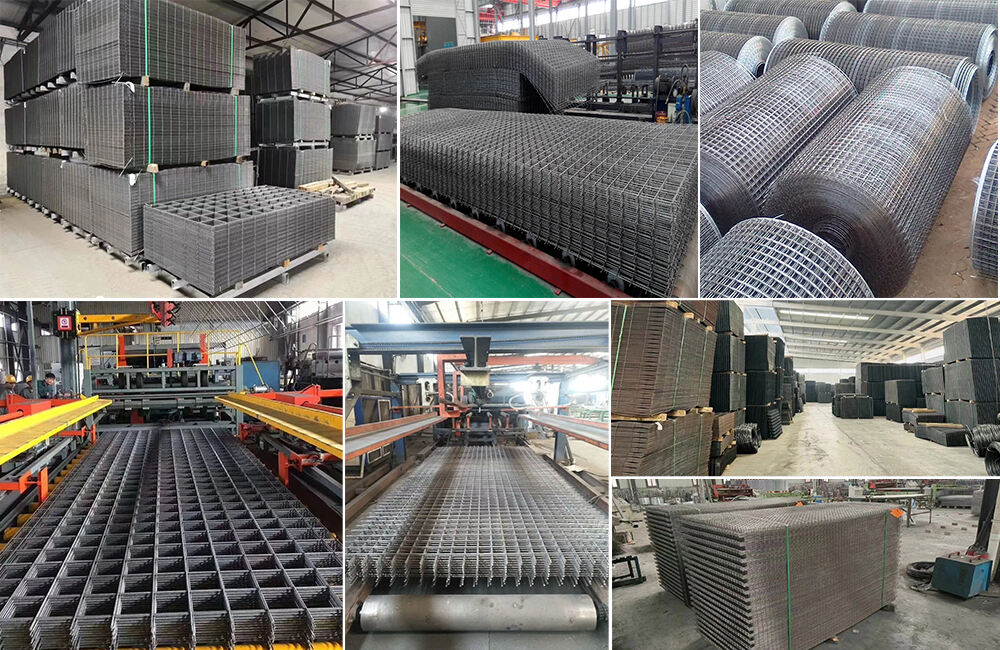

Reinforcement mesh

Steel mesh is also known as: welded steel mesh, reinforcing bar welding net, reinforcing steel welding net, reinforcing steel welding mesh, reinforcing steel mesh and so on. The longitudinal reinforcement and the transverse reinforcement are arranged at a certain distance at a certain distance, and each of them is welded at the right angle and all the intersections are welded together.

Mechanical Properties:

Minimum Yield Limit = 500 N/mm²

Minimum Tensile Strength = 550 N/mm²

Minimum Elongation at Break = 5%, 8%

Raw material = SAE 1006, SAE 1008, SAE 1010 quality or mesh quality wire rod is used.

Product Video

Description

Concrete Reinforcing Mesh also known as steel reinforcing mesh, welded wire fabric, ribbed steel bars welded mesh and so on. Be made from cold reduced Wire or cold rolled ribbed bar, It is in the same or different diameters of the vertical and horizontal steel bars , and has a rectangular or square apertures and is produced in flat sheets. It is used to provide tensile strength and crack control to structural concrete elements.

Product Parameter

| Product name | Reinforcement mesh |

| Standard | ASTM AISI JIS Etc |

| material | Q195,Q235, Q355,Q345,SS400 ,S235JR,S355JR,Etc |

| Grade | HRB335/400/500 Etc |

| Length | 1-6m or customized |

| Width | 1-6m or customized |

| Diameter | 0.5-12mm or customized |

| Spacing | 50/100/150/200 or customized |

| Tolerance | ±1% |

| Technique | Hot rolled Welding |

| Sample | Avaliable |

| Certification | CE,ISO,SGS,ETC |

| MOQ | 25 TONS |

| Payment | TT,LC,ETC |

| delivery time | Usually 7 days, depending on the quantity |

| Package | Bundle, or with all kinds of colors PVC or as your requirements |

| Application | House beam, house roof, building board, wall, concrete road, bridge, airfield pavement, highway,water dam, road base and constructions, etc. |

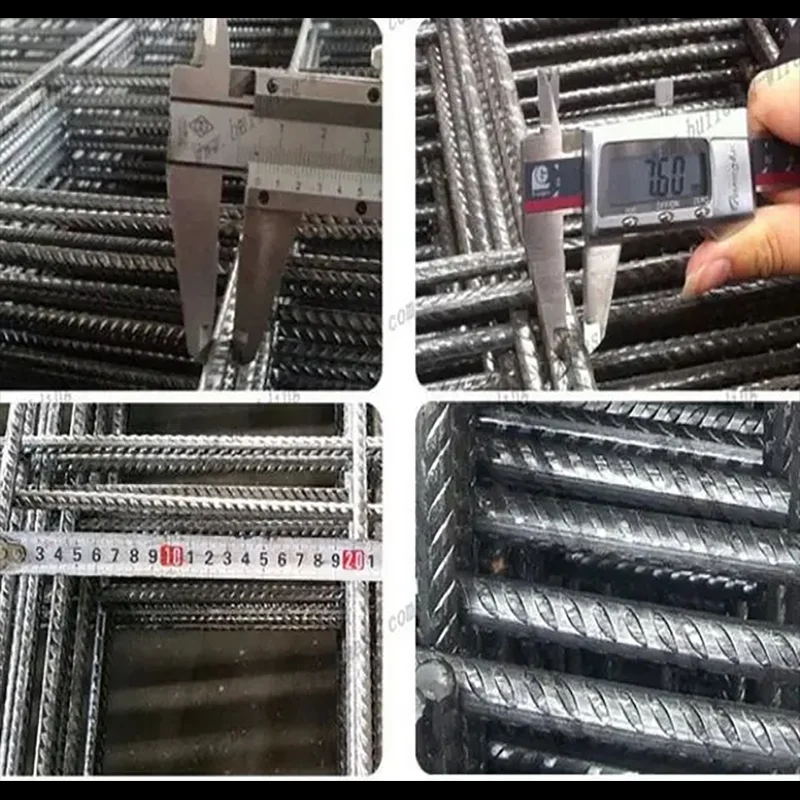

Product Show

The construction of the reinforcement mesh is made of high-quality low-carbon steel wire, cold-rolled ribbed steel bars or cold-rolled round steel bars for stainless steel wire at right angles to the longitudinal and transverse directions, and all are inserted through the electric welding according to a certain distance. Beforehand, the greasy surface, paint stain, cement slurry and floating skin and rust etc. of the steel bar should be clear and clean. After the processing is completed, the reinforced mesh should be flat, and the surface of the reinforced steel should not be damaged by weakening the cross-section of the reinforced steel. Straighten the steel bar first, and then cut it into steel bars. The scale of the reinforced mesh is summarized and considered according to the distance between the arch and the degree of overlap between the mesh.

| Handset display (type) |

Diameter wire | Wire distance | Handset display (type) |

Diameter wire | Wire distance | ||||

| Longitudinal D | Transverse | Longitudinal a | Transverse t | Longitudinal D | Transverse d | Longitudinal a | Transverse t | ||

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | ||

| Q 84 | 4,0 | 4,0 | 150 | 150 | R 84 | 4,0 | 4,0 | 150 | 250 |

| Q 92 | 4,2 | 4,2 | 150 | 150 | R 92 | 4,2 | 4,0 | 150 | 250 |

| Q 111 | 4,6 | 4,6 | 150 | 150 | R 111 | 4,6 | 4,0 | 150 | 250 |

| Q 126 | 4,0 | 4,0 | 100 | 100 | R 126 | 4,0 | 4,0 | 100 | 250 |

| Q 131 | 5,0 | 5,0 | 150 | 150 | R 131 | 5,0 | 4,0 | 150 | 250 |

| Q 139 | 4,2 | 4,2 | 100 | 100 | R 139 | 4,2 | 4,0 | 100 | 250 |

| Q 166 | 4,6 | 4,6 | 100 | 100 | R 166 | 4,6 | 4,2 | 100 | 250 |

| Q 188 | 6,0 | 6,0 | 150 | 150 | R 188 | 6,0 | 4,0 | 150 | 250 |

| Q 196 | 5,0 | 5,0 | 100 | 100 | R 196 | 5,0 | 4,2 | 100 | 250 |

| Q221 | 6,5 | 6,5 | 150 | 150 | R 221 | 6,5 | 4,6 | 150 | 250 |

| Q 238 | 5,5 | 5,5 | 100 | 100 | R 238 | 5,5 | 4,2 | 100 | 250 |

| Q 257 | 7,0 | 7,0 | 150 | 150 | R 257 | 7,0 | 5,0 | 150 | 250 |

| Q 283 | 6,0 | 6,0 | 100 | 100 | R 283 | 6,0 | 4,0 | 100 | 250 |

| Q 331 | 6,5 | 6,5 | 100 | 100 | R 331 | 6,5 | 4,6 | 100 | 250 |

| Q 335 | 8,0 | 8,0 | 150 | 150 | R 335 | 8,0 | 5,0 | 150 | 250 |

| Q 378 | 8,5 | 8,5 | 150 | 150 | R 378 | 8,5 | 5,0 | 150 | 250 |

| Q 385 | 7,0 | 7,0 | 100 | 100 | R 385 | 7,0 | 5,0 | 100 | 250 |

| Q 424 | 9,0 | 9,0 | 150 | 150 | R 424 | 9,0 | 6,0 | 150 | 250 |

| Q 442 | 7,5 | 7,5 | 100 | 100 | R 442 | 7,5 | 5,5 | 100 | 250 |

| Q 503 | 8,0 | 8,0 | 100 | 100 | R 503 | 8,0 | 6,0 | 100 | 250 |

| Q 524 | 10,0 | 10,0 | 150 | 150 | R 524 | 10,0 | 6,0 | 150 | 250 |

| Q 567 | 8,5 | 8,5 | 100 | 100 | R 567 | 8,5 | 6,0 | 100 | 250 |

| Q 577 | 10,5 | 10,5 | 150 | 150 | R 577 | 10,5 | 6,0 | 150 | 250 |

| Q 636 | 9,0 | 9,0 | 100 | 100 | R 636 | 9,0 | 6,0 | 100 | 250 |

| Q 709 | 9,5 | 9,5 | 100 | 100 | R 709 | 9,5 | 6,0 | 100 | 250 |

| Q 785 | 10,0 | 10,0 | 100 | 100 | R 785 | 10,0 | 6,0 | 100 | 250 |

| 1.GERMAN STANDARD DIN488 (SIZE:2150MMX5000MM) | ||||||

| Ref No. | Std Unit | Longitudinal Wires(mm) |

Cross Wire(mm) |

Pitch of Wire(mm) |

Mass (Kg) |

Mass (Kg/m2) |

| Q131 | Sheet | 5 | 5 | 150@150 | 22.476 | 2.091 |

| Q181 | Sheet | 6 | 6 | 150@150 | 32.401 | 3.014 |

| Q221 | Sheet | 6.5/5.0 | 6.5 | 150@150 | 33.707 | 3.316 |

| Q295 | Sheet | 7.5/5.5 | 7.5 | 150@150 | 44.245 | 4.116 |

| Q378 | Sheet | 8.5/6 | 8.5 | 150@150 | 66.659 | 5.157 |

| 2. Australia/New Zealand standard AS/NZS 4671:2001(SIZE:6000X2400mm) | |||||

| Ref No. | Std Unit | Longitudinal Wires(mm) |

Edge wires (mm) |

Cross Wires(mm |

Mass(Kg) |

| SL81(F81) | Sheet | 7.6@100 | 7.60@100 | 7.60@100 | 105 |

| SL102(F102) | Sheet | 9.5@200 | 6.75@100 | 9.50@200 | 80 |

| SL92(F92) | Sheet | 8.6@200 | 6@100 | 8.60@200 | 66 |

| SL82(F82) | Sheet | 7.6@200 | 5.37@100 | 7.60@200 | 52 |

| SL72(F72) | Sheet | 6.75@200 | 4.77@100 | 6.75@200 | 41 |

| SL62(F62) | Sheet | 6@200 | 4.77@100 | 6@200 | 33 |

| SL52(F52) | Sheet | 4.77@200 | 4.77@100 | 4.77@200 | 21 |

| 3.BRITISH STANDARD BS4483 | ||||||

| Ref No. | Std Unit | Longitudinal Wires(mm) |

Cross Wires(mm |

Pitch of wire (mm) |

No.of sheet per ton |

Mass (kg/m2) |

| A393 | Sheet | 10 | 10 | 200@200 | 15 | 6.16 |

| A252 | Sheet | 8 | 8 | 200@200 | 22 | 3.95 |

| A193 | Sheet | 7 | 7 | 200@200 | 29 | 3.02 |

| A142 | Sheet | 6 | 6 | 200@200 | 40 | 2.22 |

| A98 | Sheet | 5 | 5 | 200@200 | 57 | 1.54 |

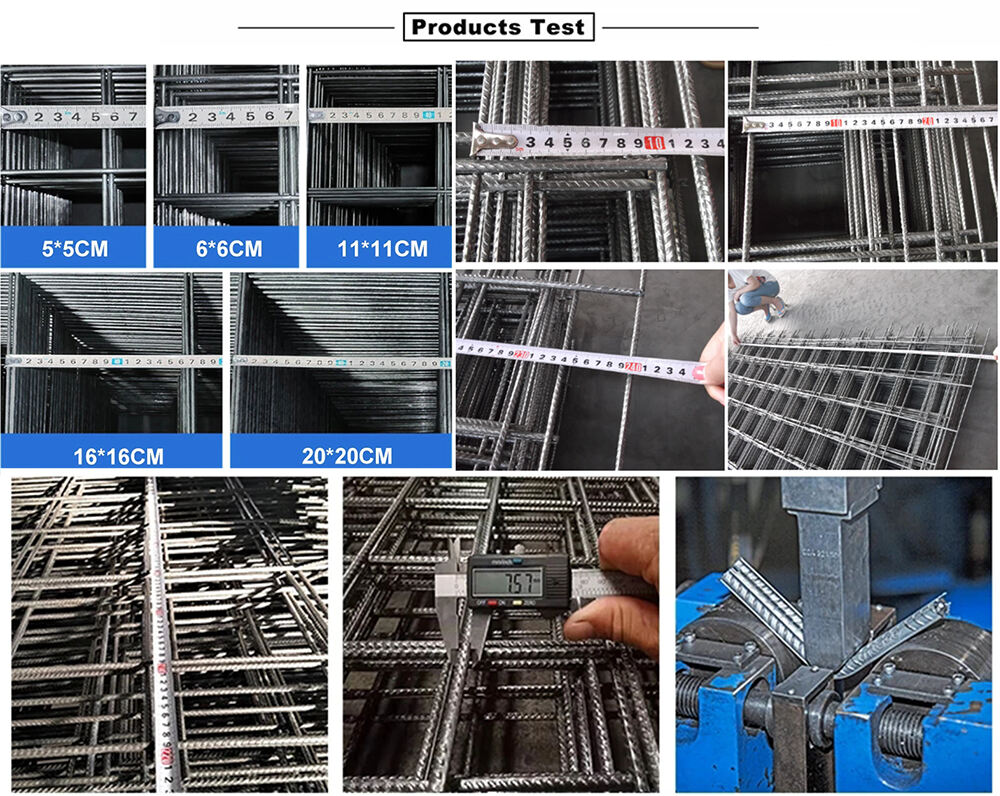

Strict Quality Control:

1. During and after production, 4 QC staffs with more than 5 years experience inspect products in random.

2. National accredited laboratory with CNAS certificates

3. Acceptable inspection from third party appointed/paid by buyer, such as SGS, BV.

Product features

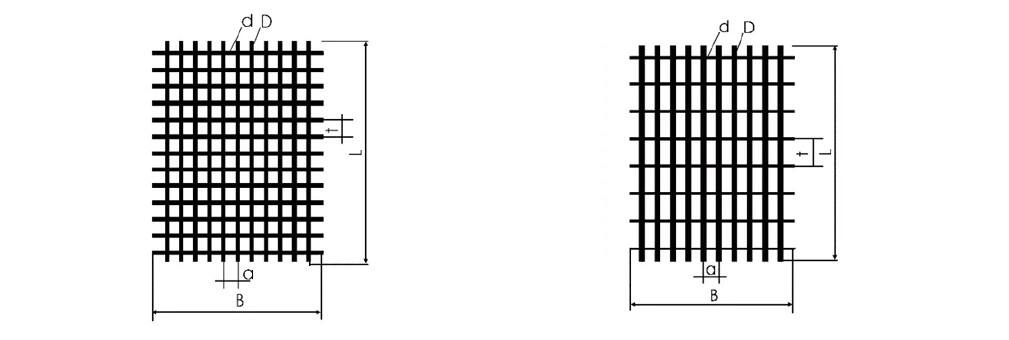

① Ribbed Square Reinforcing Mesh

The square reinforcing mesh is a universal galvanized grid plate, which ismanufactured of high-quality ribbed steel rebars and is used for flat concretereinforcement. The L-grade ribbed steel rebars are welded together at equalintervals to form a square hole pattern.Ribbed square reinforcing mesh is a multifunctional reinforcing fabric used inmodern concrete structures. Widely used in reinforced concrete slabs fordriveways, patios, pavement areas, sheds, precast panels, and other flatconcrete elements.All the ribbed square mesh produced by Dongfu can be manufacturedaccording to the quality standards of different countries and regions, anddifferent sizes can be manufactured according to your specific requirements

② Ribbed Rectangular Reinforcing Mesh

Rectangular reinforcing mesh is also manufactured from L grade ribbed rebars(D500L) that are welded together with different spacing in each direction toform a rectanqulargrid.This mesh is used for reinforcing thin concrete elements such as floor slabs andwalls, patios, tilt-up slabs, and other industrial or warehouse applications,where more strength is required in one direction than the other.Our Rectanqular Rib Mesh comes in standard sheet sizes with differentlongitudinal wire options ranging from 6.75m to 11.9mm. And supportscustomization of multiple quality standards, contact us if you require specificsizes to meet your requirements.

③ Trench Mesh

Trench mesh reinforcing mesh sheets are manufactured for the purpose ofresidential footing trenches and/or industrial building concrete footing andbeam reinforcement.The main material used is Grade D500L Ribbed Reinforcement Wire. DifferentLongitudinal wires sizes are available from 7.6mm to 11.9mm. Cross wires arespaced at 300mm centers. And have dimensions of 6m lengths and widths ofdifferent sizes including 200mm to 600mm.Trench mesh common uses include rock walls, brick walls and house footing!and used specifically for residential footing trenches.All trench meshes manufactured by us comply with AS/NZS 4671-2001 SteelReinforcing Materials and support customization of special specifications andsizes

Application

Usage Areas

Areas where Standard and Special Steel Mesh are used

* In field concretes

* Concrete runway

* In highway construction

* In viaducts.

* In Prefabricated Building Elements

* In mass housing with tunnel formwork system.

* Tunnel and Metro construction

* In various constructions of industrial buildings.

* On decks and retaining walls of reinforced concrete structures.

* In Reinforced Concrete Pipes

* As a security fence

* Gabion systems

* For decorative purposes.

* In floor coverings

* In curtain concrete and retaining wall construction

* In columns, columns and beams

* In water structures, dams, canals and flumes

* Apart from these, it is used in garden walls, balustrades and suspended ceilings

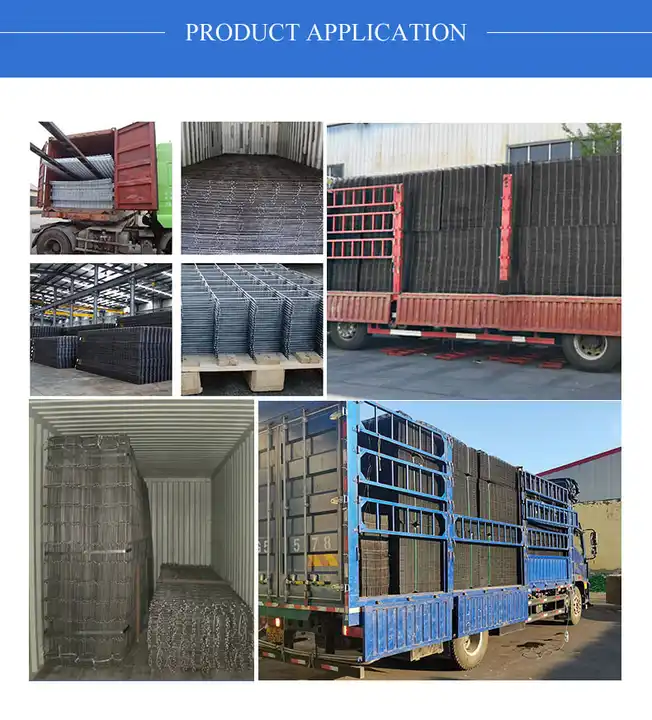

Packing & Delivery

Packaging:

In bundle with steel strip or packed in wooden pallets or as customers' requirement.

Shipping:

We have long-term cooperation with many experienced shipping companies and will find the most suitable transportation mode for

you.Can also use the customer's own freight forwarder.

Packing Details :Export standard package,bundled or be required.

The inner size of container is below:

20ft GP: 5.8m(length) x2.13m(width) x 2.18m(high)

40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high)

40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high)

Delivery Details : 7-15 days,or according to the order quantity or upon negotiation

Customer Feedback

FAQ

Q: Will you delivery the goods on time?

A: Yes,we promise to provide best quality products and delivery on time .Honesty is our company's tenet.

Q: Do you provide samples ? is it free or extra ?

A: The sample could can provide for customer with free,but the courier freight will be covered by customer account.

Q: Do you accept the third party inspection?

A: Yes absolutely we accept.

Q: How could you guarantee your products?

A: Each piece of products is manufactured by certified workshops, inspected byRUNHAIpiece by piece according to national QA/QC standard. We also could issue the warranty to customer to guarantee the quality.

Q: How do we trust your company?

A: We specialise in steel business for years, headquarter locates in Jinan, Shandong province, you are welcome to investigate in any ways, by all means, you could place an order with trade assurance which could secure your payment.

Q: How can I get your quotation as soon as possible?

A: The email and fax will be checked within 24 hours,meanwhile,theFacebook,Skype,Wechat and WhatsApp will be online in 24 hours.Please send us your requirement and order information,specification(Steel grade,size,quantity,destination port),we will work out a best price soon.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

BN

BN

BS

BS

LO

LO

MN

MN