RUNHAI STEEL

Your Reliable Steel SupplierRunhai steel is not only a professional steel supplier, but also your trustworthy partner in China. We ensure quality and quantity, provide material certificates, and will refund if the products are not qualified, so please be assured the purchase. Regarding long-term cooperation or large orders, you can contact us for additional discounts.

Enjoy Bulk Order DiscountsFOUR REASONS TOCHOOSE US

-

AAA Level

Credit Steel Supplier

Gold Certified Merchant

-

20+

Have our own R&D team

Large inventory Warehouses

-

Support

Three-party Inspection

-

Large Order

Preferential Policies

Get in touch

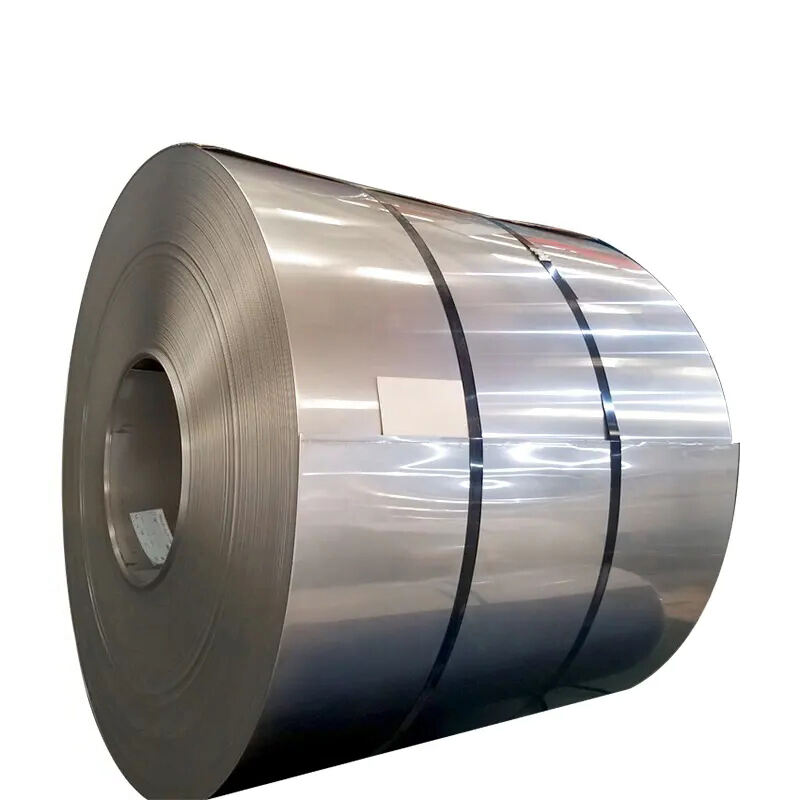

Nickel alloy coil strip

Nickel alloy is an alloy based on nickel and added with other elements. The Monel alloy containing about 30% copper, produced around 1905, is an earlier nickel alloy. Nickel has good mechanical, physical and chemical properties. Adding appropriate elements can improve its oxidation resistance, corrosion resistance, high temperature strength and improve certain physical properties. Nickel alloys can be used as materials for electron tubes, precision alloys (magnetic alloys, precision resistance alloys, electrothermal alloys, etc.), nickel-based high-temperature alloys, nickel-based corrosion-resistant alloys, and shape memory alloys. Nickel alloys are widely used in sectors such as energy development, chemicals, electronics, navigation, aviation and aerospace.

Description

Alloy steel has higher strength and toughness than carbon steel, and its reinforcement effect with the increace of tissue imbalance and tend to be more obvious, and the strength of the alloy steel annealing state than carbon steel has a lot of advantages, and in normalizing, than obviously increase the carbon steel and the strength of the alloy steel after quenching and tempering, the steel reinforcement effect is the most significant. Some alloy steels have excellent thermal hardness and other special properties, such as heat resistance, corrosion resistance, wear resistance and magnetic properties.

Product Parameter

| Product name | Nickel Alloy coil/strip |

| Grade | Nickel : Nickel200/201/205 Hastelloy:HastelloyB/-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g Hastelloy B/ UNS N10001,Hastelloy B-2/ UNS N10665 / DIN W.Nr. 2.4617,Hastelloy C, Hastelloy C-4 / UNS N06455 / DIN W. Nr. 2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr. 2.4602, Hastelloy C-276 / UNS N10276 / DIN W. Nr. 2.4819,Hastelloy X / UNS N06002 / DIN W. Nr. 2.4665 Haynes:Haynes 230/556/188 Inconel: Inconel 600/601/602CA/617/625/713/718/738/X-750,Carpenter 20 Inconel 718 / UNS N07718 / DIN W. Nr. 2.4668,Inconel 601 / UNS N06601 / DIN W. Nr. 2.4851, Inconel 625 / UNS N06625 / DIN W. Nr. 2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr.2.4669,Inconel 600 / UNS N06600 / DIN W. Nr. 2.4816 Incoloy: Incoloy 800/800H/800HT/825/925/926; Monel: Monel 400/K500/R405;etc. |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Thickness | 0.1-20 mm or as requirement |

| Width | 1000-6000 mm or as requirement |

| Length | By coil or Customized |

| Surface | Mill,polished,bright,oiled,hair line,brush,mirror,sand blast,or as required. |

| Certificates | CE,ISO,SGS,ETC |

| MOQ | 6 tons |

| delivery time | Usually 7 days, depending on the quantity |

| Package | Export standard package: bundled wooden box, suit for all kinds of transport,or be required |

| Application | High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines,etc |

| DIN/EN | UNS No | Generic term | Material | |

| 1 | 2.4060 | N02000 | Nickl200 | 99Ni-0.15Fe-0.2Mn-0.1Si-0.1Cu-0.1C |

| 2 | 2.4601 | NO2201 | Nickl201 | 99Ni-0.15Fe-0.2Mn-0.1Si-0.1Cu-0.01C |

| 3 | 2.4050 | N02270 | Nickl270 | 99.9Ni-0.02Fe-0.001Mn-0.002Si-0.005Cu- 0.01C |

| 4 | 1.4980 | S66286 | INCOLOY Alloy A286 | 25Ni-15Cr-1.5Mo-2Ti-1Mg-0.03C |

| 5 | N08367 | INCOLOY Alloy 25- 6HN |

25Ni-20Cr-6.3MO-0.25Cu-0.2N-0.01P-0.05S- 0.01C |

|

| 6 | 1.4529 | N08926 | INCOLOY Alloy 25- 6Mo |

25Ni-20Cr-6.5Mo-1Cu-0.2N-1.0Mg-0.01P- 0.005S-0.01C |

| 7 | 2.4460 | N08020 | INCOLOY Alloy 20 | 36Ni-21Cr-3.5Cu2.5Mo-1Mn-0.01C |

| 8 | 1.4563 | N08028 | INCOLOY Alloy 28 | 32Ni-27Cr-3.5Mo-1Cu-0.01C |

| 9 | 1.4886 | N08330 | INCOLOY Alloy 330 | 35Ni-18Cr-2Mg-1SI-0.03C |

| 10 | 1.4876 | N08800 | INCOLOY Alloy 800 | 32Ni-21Cr-0.3~1.2(Al+Ti)0.02C |

| 11 | 1.4876 | N08810 | INCOLOY Alloy 800H | 32Ni-21Cr-0.3~1.2(Al+Ti)0.08C |

| 12 | 2.4858 | N08825 | INCOLOY Alloy 825 | 42Ni-21Cr-3Mo-2Cu-0.8Ti-0.1AI-0.02C |

| 13 | 2.4816 | N06600 | Inconel 600 INCOLOY Alloy 600 |

72Ni-151Cr-8Fr-0.2Cu-0.02C |

| 14 | 2.4851 | N06601 | Inconel 601 INCOLOY Alloy 601 |

60Ni-22Cr-1.2Al-0.02C |

| 15 | 2.4856 | N06625 | Inconel 625 INCOLOY Alloy 625 |

58Ni-21Cr-9Mo-3.5Nb-1CO-0.02C |

| 16 | 2.4856 | N06626 | Inconel 600LCF INCOLOY Alloy 625LCF |

58Ni-21Cr-9Mo-3.5Nb-1CO-0.02C |

| 17 | 2.4606 | N06686 | Inconel 686 INCOLOY Alloy 686 |

57Ni-21Cr-16Mo-4W-0.01C |

| 18 | 2.4642 | N06690 | Inconel 690 INCOLOY Alloy 690 |

58Ni-30Cr-9Fe-0.2Cu-0.02C |

| 19 | 2.4668 | N07718 | Inconel 718 INCOLOY Alloy 718 |

52Ni-19Cr-5Nb-3Mo-1Ti-0.6Al-0.02C |

| 20 | 2.4669 | N07750 | Inconel X750 INCOLOY Alloy 750 |

70Ni-15Cr-6Fe-2.5Ti-0.06Al-1Nb-0.02C |

| 21 | 2.4360 | N04400 | MONEL400 | 63Ni-32Cu-1Fe-0.1C |

| 22 | 2.4375 | N05500 | MONEL K-500 | 63Ni-30Cr-1Fe-3Al-0.6Ti-0.1C |

| 23 | 2.4819 | N10276 | Hastelloy C-276 | 57Ni-16Mo-16Cr-5Fe-4W-2.5Co-1Mn-0.35V- 0.08Si-0.01C |

| 24 | 2.4610 | N06455 | Hastelloy C-4 | 65Ni-16Cr-16Mo-0.7Ti-3Fe-2Co-1Mn-0.08Si- 0.01C |

| 25 | 2.4602 | N06022 | Hastelloy C-22 | 56Ni-22Cr-13Mo-3Fe-2.5Co-0.5Mn-0.35V- 0.08Si-0.01C |

| 26 | 2.4675 | N06200 | Hastelloy C-2000 | 59Ni-23Cr-16Mo-1.6Cu-0.08Si-0.01C |

| 27 | 2.4665 | N06002 | Hastelloy X | 47Ni-22Cr-18Fe-9Mo-1.5Co-0.6W-0.1C-1mn- 1Si-0.008B |

| 28 | 2.4617 | N10665 | Hastelloy B-2 | 69Ni-28Mo-0.5Cr-1.8Fe-3W-1.0Co-1.0Mn- 0.01C |

| 29 | 2.4660 | N10675 | Hastelloy B-3 | 65Ni-28.5Mo-1.5Cr-1.5Fe-3W-3Co-3Mn-0.01C |

| 30 | N06030 | Hastelloy G-30 | 43Ni-30Cr-15Fe-5.5Mo-2.5W-5Co-2Cu-1.5Mn- 0.03C |

|

| 31 | N06035 | Hastelloy G-35 | 58Ni-33Cr-8Mo-2Fe-0.6Si-0.3Cu-0.03C | |

| 32 | 1.4562 | N08031 | Nicrofer hMo31 | 31Ni-27Cr-6.5Mo-1.2Cu-2mn-0.01C |

| 33 | 2.4605 | N06059 | Nicrofer hMo59 | 59Ni-23Cr-16Mo-1.0Fe-0.01C |

Physical properties

Table 6- Typical Mechanical-Property Rangesa

| Form and Condition | Tensile Strength |

Yield Strength (0.2% Offset) |

Elongation, % | Hardness, Rockwell | ||

| ksi | MPa | ksi | MPa | |||

| Rod and Bar | ||||||

| Cold-Drawn | ||||||

| Annealed | 80-100 | 550-690 | 25-50 | 170-345 | 55-35 | 65-85B |

| As-Drawn | 105-150 | 725-1035 | 80-125 | 550-860 | 30-10 | 90B-30C |

| Hot-Finished | ||||||

| Annealed | 80-100 | 550-690 | 30-50 | 205-345 | 55-35 | 65-85B |

| Hot-Finished | 85-120 | 585-830 | 35-90 | 240-620 | 50-30 | 75-95B |

| Plate | ||||||

| Hot-Rolled | ||||||

| Annealed | 80-105 | 550-725 | 30-50 | 205-345 | 55-35 | 65-85B |

| As-Rolled | 85-110 | 580-760 | 35-65 | 240-450 | 50-30 | 80-95B |

| Sheet | ||||||

| Cold-Rolled | ||||||

| Annealed | 80-100 | 550-690 | 30-45 | 205-310 | 55-35 | 88B max. |

| Hard | 120-150 | 830-1035 | 90-125 | 620-860 | 15-2 | 24C min. |

| Strip | ||||||

| Cold-Rolled | ||||||

| Annealed | 80-100 | 550-690 | 30-45 | 205-310 | 55-35 | 84B max. |

| Spring Temper | 145-170 | 1000-1170 | 120-160 | 830-1100 | 10-2 | 30C min. |

| Tube and Pipe | ||||||

| Hot-Finished | ||||||

| Hot-Finished | 75-100 | 520-690 | 25-50 | 170-345 | 55-35 | |

| Annealed | 75-100 | 520-690 | 25-50 | 170-345 | 55-35 | |

| Cold-Drawn | ||||||

| Annealed | 80-100 | 550-690 | 25-50 | 170-345 | 55-35 | 88B max. |

| Wireb | ||||||

| Cold-Drawn | ||||||

| Annealed | 80-120 | 550-830 | 35-75 | 240-520 | 45-20 | |

| No.1 Temper | 105-135 | 725-930 | 70-105 | 480-725 | 35-15 | |

| Spring Temper | 170-220 | 1170-1520 | 150-210 | 1035-1450 | 5-2 | |

Product Show

Monel alloy has excellent corrosion resistance to reducing media, and has good stability in hydrofluoric acid, alkali, seawater, H2S, H2SO4, H3PO4, organic acid and many other corrosive media, especially in hydrofluoric acid and alkali solutions, less stable than platinum and silver. The alloy has a certain SCC sensitivity and the working temperature is less than 200℃.Monel 400 copper-nickel alloy has high strength over wide temperature ranges (up to 1000F). Monel 400 springs can be used in corrosive applications up to 450F. The alloy performs well in high concentrations of salt water. Corrosion rates in surging seawater do not exceed 1 mpy. The most common specification for Monel 400 is ASTM B 164.

① Nickel-based high-temperature alloy plate

The main alloying elements are chromium, tungsten, molybdenum, cobalt, aluminum, titanium, boron, zirconium, etc. It has high strength and resistance to oxidation and gas corrosion at high temperatures of 650 to 1000°C. It is the most widely used alloy with the highest high temperature strength among high temperature alloys, manufacture aero-engine blades and high-temperature components

② Nickel-based corrosion-resistant alloy plate

The main alloying elements are copper, chromium and molybdenum. It has good comprehensive performance and can resist various acid corrosion and stress corrosion. The earliest application was nickel-copper alloy, also known as Monel alloy; in addition, there are nickel-chromium alloy, nickel-molybdenum alloy, nickel-chromium-molybdenum alloy, etc. Used to manufacture various corrosion-resistant parts.

③ Nickel-based wear-resistant alloy plate

The main alloying elements are chromium, molybdenum, and tungsten, and also contain small amounts of niobium, tantalum, and indium. In addition to its wear resistance, also has good anti-oxidation, corrosion resistance and welding properties. It can be used to manufacture wear-resistant parts, as a coating material to cover the surface of other base materials through surfacing and spraying processes.

Product features

Feature:

①Different grades

Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements.

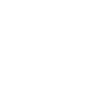

②Different surfaces

Stainless steel can be customized for different surfaces, and different surfaces have different applications. For example, 8k mirrors are generally used for decoration.

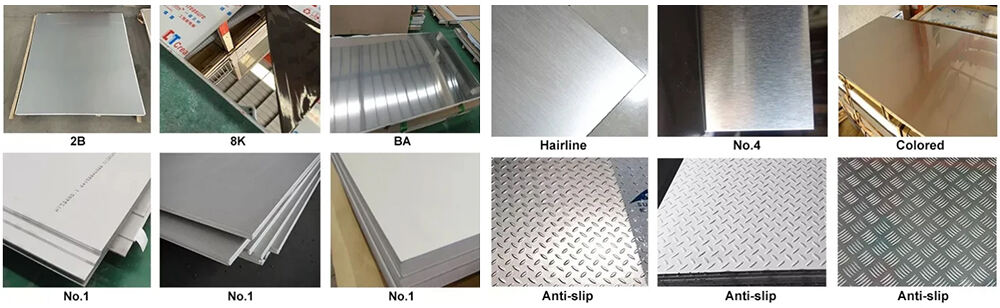

③High Quality

We have more than 30 years of experience in this industry and believe that we can satisfy any demand for stainless steel raw materials.

We have a strict detection system to support three-way detection.

Application

Nickel alloys can be used in the following industries:

As a kind of higher material steel coil, alloy steel coil is widely used in chemical equipment,off-shore oil driling companies,power generation,gas processing,specialty chemicals,sea water equipment,pharmaceuticals,petrochemicals and more.

High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines.

Packing & Delivery

1. Package:export sea worthy package + water proof paper + wooden pallet or as customers' requirements.

2. The inner size of container is below:

20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high)

40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high)

40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high)

3.Delivery Details :7-15 dyas,or according to the order quantity or upon negotiation.

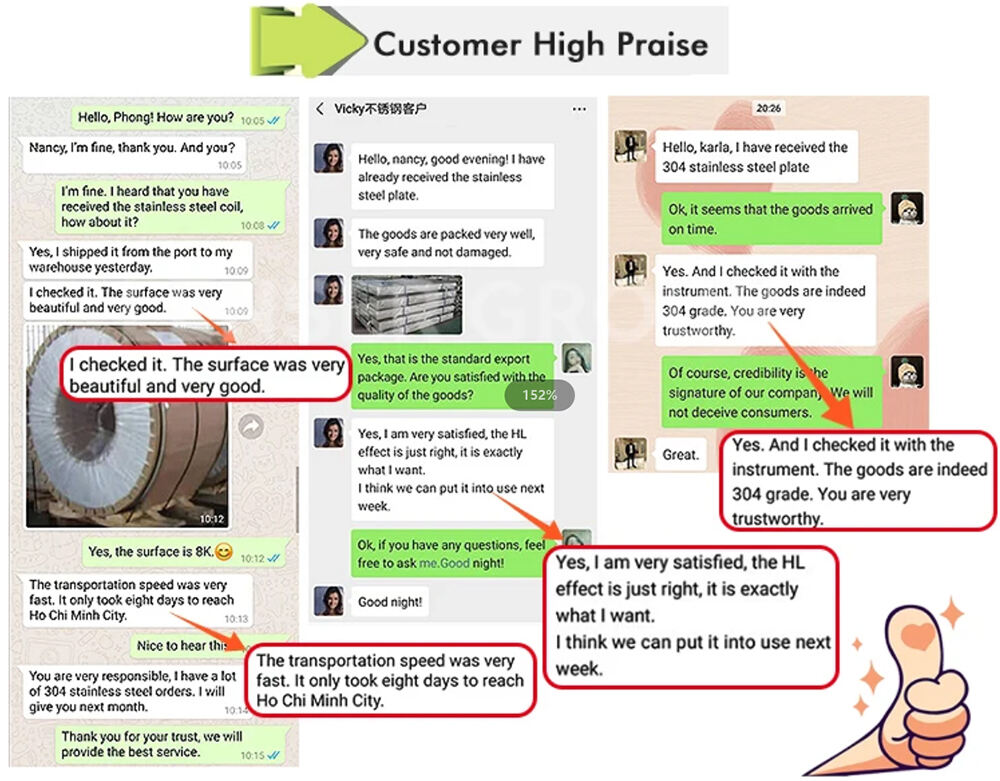

Customer Feedback

FAQ

Q: Will you delivery the goods on time?

A: Yes,we promise to provide best quality products and delivery on time .Honesty is our company's tenet.

Q: Do you provide samples ? is it free or extra ?

A: The sample could can provide for customer with free,but the courier freight will be covered by customer account.

Q: Do you accept the third party inspection?

A: Yes absolutely we accept.

Q: How could you guarantee your products?

A: Each piece of products is manufactured by certified workshops, inspected byRUNHAIpiece by piece according to national QA/QC standard. We also could issue the warranty to customer to guarantee the quality.

Q: How do we trust your company?

A: We specialise in steel business for years, headquarter locates in Jinan, Shandong province, you are welcome to investigate in any ways, by all means, you could place an order with trade assurance which could secure your payment.

Q: How can I get your quotation as soon as possible?

A: The email and fax will be checked within 24 hours,meanwhile,theFacebook,Skype,Wechat and WhatsApp will be online in 24 hours.Please send us your requirement and order information,specification(Steel grade,size,quantity,destination port),we will work out a best price soon.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

BN

BN

BS

BS

LO

LO

MN

MN