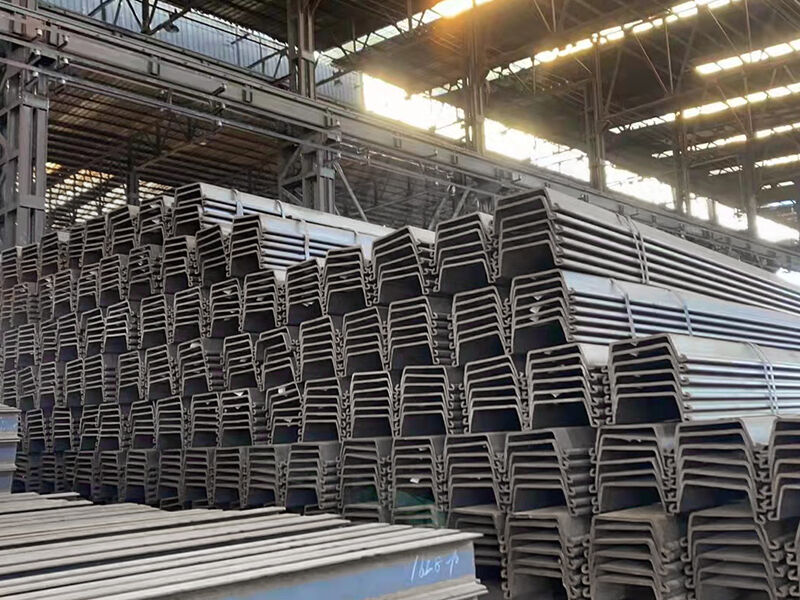

The decision on the correct specifications of the cold-formed sheet piles forms a serious engineering decision, and it has direct impact on the project in aspects of safety, costs and project life. They are fine interlocked sheets of steel that are needed in construction of retaining wall, flood wall, basement and cofferdam. Although this is a common experience of them during the short-term, the selection of a right product in the short term determines the future performance of a particular product. Unlike the hot-rolled sheet piles, the cold-formed piles are manufactured by bending at room temperature steel strip or plate, therefore producing lighter economical components that could be introduced in several medium heavy-duty applications.

These are the key factual parameters that need to be taken into consideration in order to make an informed specification.

Understand the Project's Primary Function and Environment

The performance of steel sheet pile is dependent on the performance that it is expected to do. The questions which stand behind are these:

Permanent or Temporary? Temporary cofferdams are defined as being easily setup and dismantled (can be reused), permanent retaining walls must be more long-term and expensive to be worn out through corrosion with time.

What is it Retaining? Write about what has been left behind: the nature of soil, the quantity of water, and chemicals. Such an example is Sandy soils that are not described in terms of closely knit pressures as cohesive clays.

Environmental Conditions? Is it salty water, urban (peaceful chemicals) or rural? It is the potential of corrosion and the need of coating.

Installation Equipment available: The installation pile section to be used must be in accordance to the provided impact hammers or vibratory hammers such as their weight, size and interlock strength.

Key Technical Specifications to Evaluate

The main technical requirements that should be considered in the project provided the case are:

A. Section Modulus (Z):

What it means: The significance of structural capacity measures. It is the indication of the ability of a section to resist the ability of bending.

Its practice: The estimation of the soil and water pressure bending will be done using the geotechnical analysis. The chosen sheet pile should be a steel sheet pile whose calculated demand is the same or even higher demand of the calculated demand with appropriate factor of safety. One of the risks in this case is under-specification which leads to structural failure.

B. Interlock Strength:

What it is: Separating intermediate strength of the piles between the following ones is customarily determined in kilo-newtons per meter or pounds per foot.

Application: It must be able to pass shear forces on the wall line. The required final force depends on the depth of wall and the bending moment. An interlock is loosely fitted and can be unlocked under a state of stress.

C. Steel Grade and Strength Yield:

What that is: The material nature of the steel strip, e.g. S355GP (minimum yield strength of 355 Mpa) on EN 10249 or any ASTM standard.

Application Higher yield strength allows to use a finer and lighter section where the same section modulus is required, and would have the possible effect of reducing the material and transportation costs. The steels of utmost grade may not be more ductile and this may also impact on the hard soil driving.

D. Dimensions and Weight:

What this involves: The depth of the pile as a whole, the thickness of the web/flange and the width of individual panels as well as the weight per square meter.

Application: Thick walls are those that are stronger in nature and are of high section modulus. The use and construction of light spaces are less demanding. The other is tradeoff between the structure requirement, corrosion allowance and installation logistics.

E. Coating and corrosion Protection:

What it is: Coatings are mandatory on either hostile environment or long term works.

Applications: It is usually applied as a hot-dip galvinizing or polymeric finish. The nature and thickness of coating to be employed (e.g. number of microns of zinc) will be necessary and will be dependent on recommendations of the site surveys or standard guidelines like ISO 12944, depending on the design life of the project and prediction of corrosion rate.

The Specification Process: A Step-by-Step Approach

Geotechnical Investigation: Obtain a report on soil (parameters (soil type, cohesion, friction angle, water table).

Computation of Load: Load professional engineer must compute the lateral earth and water pressure after which bending moment shear and interlock strength which would be needed at the depth of the wall in question are to be computed.

First Selection: Choose 2-3 elements of the pile according to the manufacturer datasheets not those the section modulus of which and the interlock strength of which are inferior to the calculated requirements.

Lifecycle Cost Analysis: Decisions Compare the first price, installation price (easy to drive) and long term maintenance (corrosion protection) of the shortlist. What may be the cheapest in the 50-year life cycle may not be the cheapest pile in the first place.

Review and Finalize: This is to ensure final decision is not contradictory to all the available local building and material specifications (e.g. EN 10249, ASTM A572/A572M).

Conclusion: Precision Ensures Performance

Cold-formed sheet pile specifications are a trade-off in the geotechnical science, structural mechanics and applied economics. It is not always clear to the one that the best pile is the best, simply the best of your situation on the ground, loads on the structure beneath it and your projects. The paramount importance has been on professional judgment and usage of right data of an engineer.

In such undertaking, Shandong Runhai Stainless Steel Co., Ltd. will be engaged in providing full material that will be interested in steel sheet piles and other steel products that are specifications based and reliable. Our stocks of our carbon steel, galvanized steel products, are numerous and can be produced and can meet the requirement of your projects at the economical logistics. The WMS and CRM systems are technologically advanced and allow us to be precise in processing the orders and organizing the deliveries based on the requirements of the construction, power, and civil engineering industry with the help of a powerful combination with the local supply chains.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

BN

BN

BS

BS

LO

LO

MN

MN