The application of pipe casing for underground pipeline offers numerous advantages. One major advantage is that it reduces the risk of damage to the pipelines. Without pipe casing, pipelines may be crushed or punctured by rocks or roots, causing leaks. Pipelines are guarded with casing pipe for their protection. It also helps pipelines last longer because it protects them from rust and other types of damage.

While pipe casing is extremely beneficial, there may be challenges associated with its installation. A frequent challenge is aligning the pipe casing properly with the pipelines it protects. If it doesn’t line up properly, it may not protect the pipelines very well. One more issue is making sure the casing is fixed closely to the pipelines. If it's not tightly secured, it may be displaced, rendering it less effective. To address these issues, it is critical to pay close attention during installation to ensure proper alignment and secure installation. If you take the time to do this right, these challenges can be mitigated, and the pipe casing can perform their intended function effectively.

Pipe casing can be kept in good condition and protected from rust by proper maintenance. Regular checks of the casing for signs of wear is also key. By picking up on issues early, they can be addressed before they escalate. Cleaning the casing is important, too, as dirt can cause rust if left too long. After all, those casings are important to keep in good shape, so utilizing protective coatings is a great way to prevent rust. Protecting pipe casing and keeping them in good condition can make sure the pipelines of construction projects would be safe for a prolonged duration.

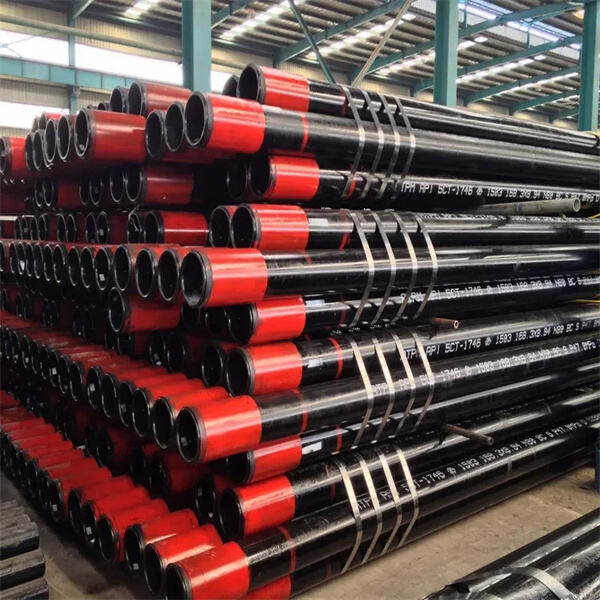

There are several factors to weigh when selecting materials for pipe casing. The most frequently used materials are steel, plastic and concrete. There are pros and cons of each material. Steel pipe casing is durable and long-lasting, which makes it suitable for projects requiring additional safety.

Pipe casing is similar to a protective shield that prevents injury to underground pipelines. When pipelines are buried in the ground, they can be hit by roots from trees and shrubs, or even the earth surrounding them. The pipelines are protected from these threats by pipe casing. A pipe casing prevents a pipeline from breaking or leaking; breakage or leakage is a big problem. Therefore, the use of pipe casing in construction projects ensures the smooth execution of everything.

Shandong Runhai Stainless Steel Co., Ltd. is Located In Jinan City, Shandong Province. It Is A Professional Steel Sales Company Integrating foreign trade and domestic trade, Factory directly supply, adequate inventory, Good Prices, and it is an in-house research and development team, supports OEM and ODM. Samples are available, we invite you come to our factory.

Our best-selling products include stainless steel plate/pipe/coil/tape, carbon steel plate/pipe/coil/tape, galvanized steel plate/pipe/coil/tape, seamless/welded steel pipe, aluminum plate/coil/pipe, PPGI/PPGL coil, ball valve pipe, HandI beam/Angle steel /UandC channel, roofing shingles, silicon steel, rebar/deformation bar, iron wire, copper pipe/plate, etc. These are utilized extensively in the pharmaceutical, chemical electric power, railway industries, as well as automobiles construction engineering, automobiles and other fields.

Our sales division can offer you aided by the quote many is recent at any time.

The central warehouse of our company is situated in Tai 'an City in Shandong Province in China. It houses a variety of inventory lines and processing lines as well as an advanced CRM management system, WMS as well as a variety of other tools to assist customers through the entire process, from product consultation purchasing, to ordering, and purchase. We can provide CE, ISO, SGS and more certifications to helpclients do business smoothly. You will get the fastest delivery times based on the quality and quantity.

Copyright © Shandong Runhai Stainless Steel Co., Ltd. All Rights Reserved.